Have you ever wondered how large organizations maintain the optimal performance of their machinery, buildings, and other physical assets? This is where Engineer Asset Management (EAM) comes into play.

EAM is a systematic process of managing and maintaining physical assets in an organization to maximize their value and efficiency. It involves various strategies and practices aimed at ensuring that these assets deliver the best possible return on investment throughout their lifecycle.

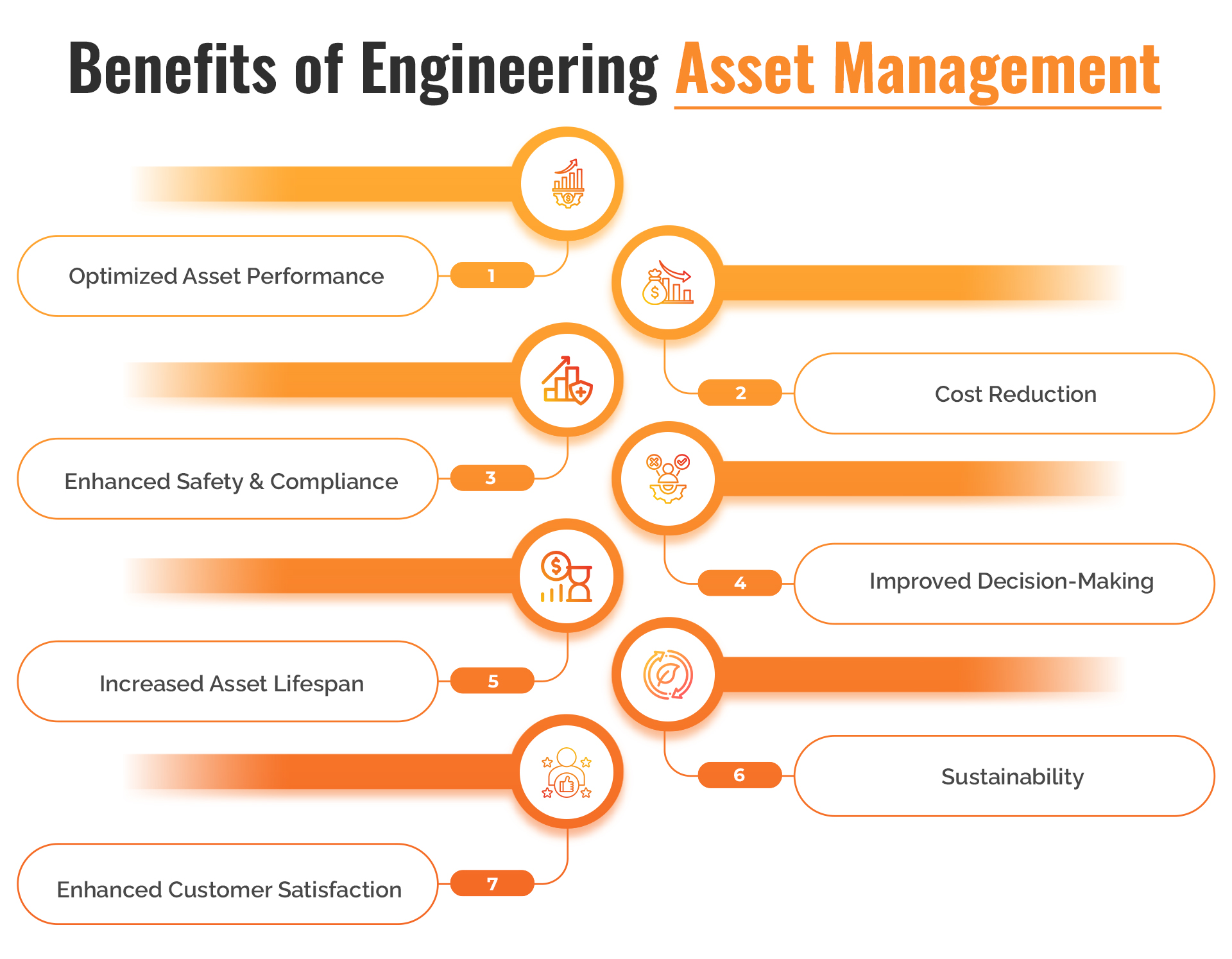

Implementing Engineering Asset Management offers numerous benefits that can significantly enhance an organization’s operations and bottom line.

One of the primary benefits of EAM is the optimization of asset performance. By continuously monitoring and maintaining assets, organizations can ensure they operate at peak efficiency. This means fewer breakdowns, less downtime, and more consistent output. For example, regular maintenance checks can identify potential issues before they become major problems, saving both time and money.

Effective EAM leads to significant cost savings. When assets are well-maintained, they tend to have a longer lifespan and require fewer repairs. This translates to lower maintenance costs and reduced need for frequent replacements. Moreover, efficient asset management can also result in better resource allocation, ensuring that investments are made where they are most needed.

Maintaining assets properly is not just about performance; it’s also about safety and compliance. Well-managed assets are less likely to fail, which reduces the risk of accidents and injuries. Additionally, EAM ensures that all assets meet regulatory standards, helping organizations avoid fines and legal issues.

With EAM, organizations have access to accurate and up-to-date information about their assets. This data-driven approach enables better decision-making. For instance, managers can use asset data to plan maintenance schedules, budget for replacements, and even decide when it’s time to retire an asset. This level of insight ensures that decisions are based on facts rather than guesswork.

Regular maintenance and timely upgrades can significantly extend the lifespan of assets. By taking proactive measures, organizations can delay the need for costly replacements. This not only saves money but also ensures that assets remain in good working condition for longer periods.

EAM contributes to sustainability efforts by promoting efficient use of resources. Properly managed assets consume less energy and produce fewer emissions. Additionally, by extending the life of assets, organizations can reduce waste and minimize their environmental footprint.

When assets operate efficiently, it directly impacts the quality of products or services delivered to customers. Reliable and well-maintained assets lead to fewer disruptions, ensuring that customers receive consistent and high-quality service. This, in turn, boosts customer satisfaction and loyalty.

If you are looking for an effective asset management solution for better management, try Genic Assets Management Software Solutions!

The roles of engineering asset management can be categorized based on organizational management levels—strategic, aggregate, and operational—as well as the nature of the asset-related activities. Here’s an analysis of the primary roles of EAM:

At the strategic level, EAM is crucial in formulating long-term plans and policies that align with the organization’s overall objectives. The strategic role involves:

At the aggregate or tactical level, EAM focuses on translating strategic plans into actionable programs and projects. This includes:

At the operational level, Engineer Asset Management involves day-to-day activities that ensure assets are used efficiently and effectively. This encompasses:

An essential role of EAM across all levels is the continuous improvement of asset management practices. This is achieved through the Plan-Do-Check-Act (PDCA) cycle, which promotes regular assessment and refinement of processes. Additionally, EAM fosters integration within the enterprise system, ensuring that asset management activities are well-coordinated and aligned with other business functions. This collaborative approach enhances the overall effectiveness and efficiency of the organization.

Engineering Asset Management (EAM) is vital for optimizing the performance and longevity of an organization’s physical assets. By implementing EAM, organizations can achieve cost efficiency, extend asset lifespan, improve performance, enhance decision-making, and ensure regulatory compliance.

The strategic, tactical, and operational roles of EAM ensure a comprehensive approach to asset management, aligning with organizational goals and fostering continuous improvement. Through effective EAM practices, businesses can maximize their return on investment, minimize downtime, and maintain seamless operations, ultimately enhancing their overall productivity and profitability.

Articles you might like

Genic Assets provide complete visibility, traceability, and accountability of your assets!

Get Started